About Us

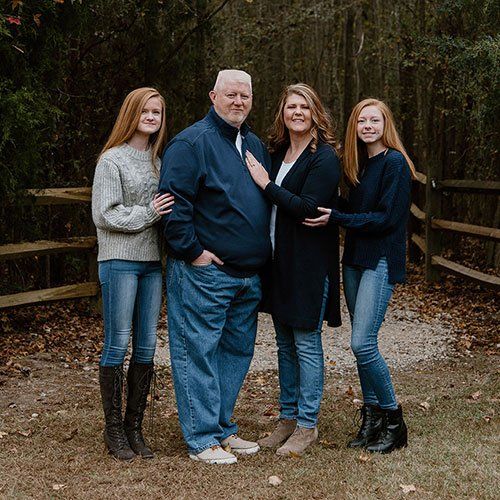

The Robinson Family

(From Left to Right: Kassidy, Tripp, Kathleen, and Megan)

Who We Are

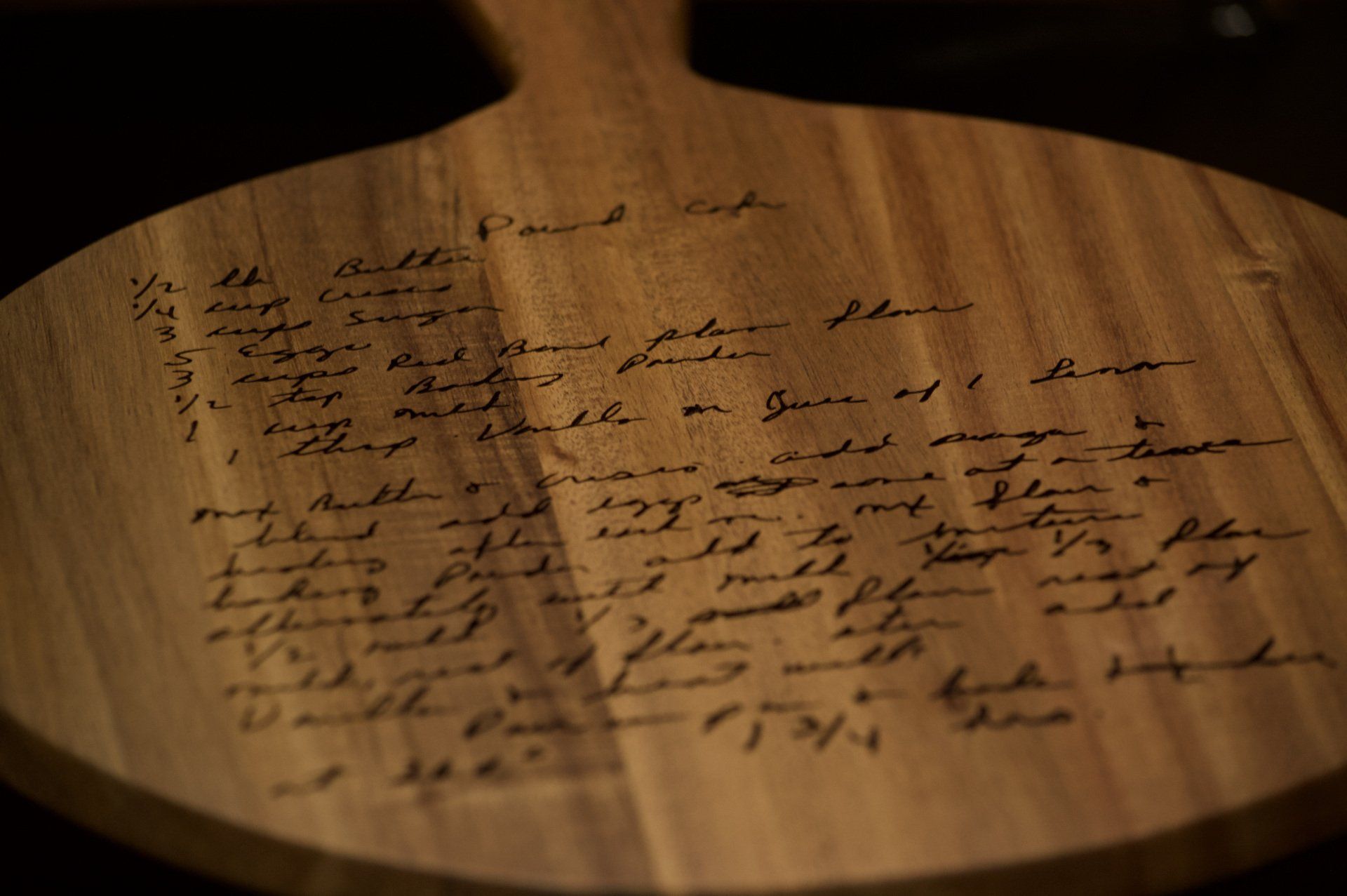

K & M Laser Works is a family-owned and operated laser engraving business that started in 2019 with a focus on customizing gifts by combining photographs, graphics, and text into unique, one-of-a-kind products as well as special fund-raising options.

We aim to create special, personalized gifts that will generate smiles and be a small piece of happiness in the lives of those you love. Never underestimate the power of a single act of kindness!

We also have the capacity to run mass jobs for industrial purposes such as serialization, barcoding, customized parts identification, and customized swag for your teams.

We are excited to provide you with online shopping and impeccable customization. We are available to answer questions to help you find special gifts or solutions to your business needs.

If you have comments or concerns about your order or the content found on this website, please feel free to contact us via telephone or email and one of our experienced team members will get back to you right away.

Thank you again for visiting our store! We look forward to developing a great relationship with you.

What We Do

When people hear the word "engraving" they probably think about deeply etched marks that can be felt with your fingertips. Depending on your experience, that might convey an image of a plastic pet tag, a silver name bracelet, or something like the tablets from the ten commandments.

In the modern age, mechanical engraving is performed with machines that use high-speed spinning metal bits to cut into materials like metal, plastic, wood, and stone.

Towards the end of the 20th century, as lasers moved from science fiction weapons to commercial applications, laser engraving machines were born. As they evolved, lasers using tubes filled with CO2 gas were able to be used in most environments - only requiring venting.

Except for wood, materials that are marked with a laser engraving machine only have a few 1,000ths of an inch of material removed. Typical materials for laser engraving are acrylic, wood, plastic, marble, and glass. Due to the wavelength of the laser light from a CO2 laser, these machines could not mark raw metal, as the light bounces off the material. However, anodized aluminum would show white marking when used with a CO2 laser, so metal products made of anodized aluminum became prolific.

In the early years of the 21st century, experimenting with laser tubes containing different gases led to the development of a new class of lasers - ones that could mark raw metal. Generating shorter wavelengths of light, the metal would absorb the light and the properties of the metal at the surface would be changed, leaving a permanent mark.

Each class of laser has its strengths and limitations. That's why K&M Laser Works uses both types to offer our customers the best of both worlds.